Dragon’s Tail

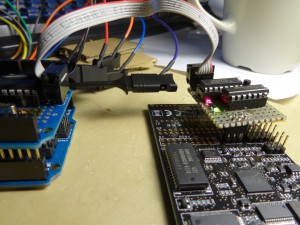

As mentioned in my previous post, AVI Dragon’s SPI pins in debugWire interface have to be disconnected during debug run in order to properly run an application that uses SPI / USI. I also noticed that the Dragon dominates RESET pin, too. In my project, I’m resetting target chip from Arduino. The Dragon is killing this functionality as well. This makes me quite uncomfortable with my development work, so I’ve enhanced the switch I made on bread board previously, and made a helper device. It’s nicely working. I named it “Dragon’s Tail”.

As mentioned in my previous post, AVI Dragon’s SPI pins in debugWire interface have to be disconnected during debug run in order to properly run an application that uses SPI / USI. I also noticed that the Dragon dominates RESET pin, too. In my project, I’m resetting target chip from Arduino. The Dragon is killing this functionality as well. This makes me quite uncomfortable with my development work, so I’ve enhanced the switch I made on bread board previously, and made a helper device. It’s nicely working. I named it “Dragon’s Tail”.

About AVR Dragon

Decoupling SPI pins from AVR Dragon

AVR Dragon provides on-chip debugging feature through debugWire interface. The debugWire utilizes the ISP six-pin header to control the target device as shown in the following link:

AVR Dragon provides on-chip debugging feature through debugWire interface. The debugWire utilizes the ISP six-pin header to control the target device as shown in the following link:

http://www.atmel.no/webdoc/avrdragon/avrdragon.section.zrr_osd_lc.html

However, the target application does not work correctly with SPI feature during debug run.

Candidates for Noise Source Transistor

Typical analog noise generators make signal by amplifying AC component coming out from zener current of transistors reversely biased between emitter and base (here’s an example circuit).

Any bipolar transistor would work as such a noise source, but noise quality in listening is different from part numbers. 2SC828A is well known as good noise source, but it’s been obsolete for long. So for Analog2.0, I have been recommending 2SC3311 instead. But this part becomes obsolete as well. Now I have to find another one.

Latency of Serial.println() with Arduino UNO

As a part of my current experiment, I’m running following piece of code:

if (digitalRead(pinDeviceReadReady) == HIGH) {

Serial.println("DATA READY");

spiSend(0x20); // command "read request"

readBuffer.deviceId = spiReceive();

Serial.println(readBuffer.deviceId);

readBuffer.wireId = spiReceive();

Serial.println(readBuffer.wireId);

readBuffer.length = spiReceive();

Serial.println(readBuffer.length);

for (int i = 0; i <= readBuffer.length; ++i) {

readBuffer.data[i] = spiReceive();

Serial.println(readBuffer.data[i]);

}

}

where

inline void spiSend(uint8_t data)

{

// wait for device ready to write

while (digitalRead(pinDeviceWriteReady) == LOW);

SPI.transfer(data);

}

inline uint8_t spiReceive()

{

while (digitalRead(pinDeviceReadReady) == LOW);

uint8_t data = SPI.transfer(0);

return data;

}

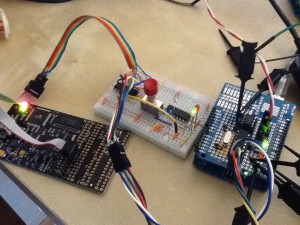

Phase one experiment

Continued from this article. I’ve done with the phase one experiment.

The goal of phase one experiment is to implement end-to-end application with minimum struggle for hardware design and implementation.

What does the application do?

I am sure there will be a lot of testing work before I put the communication device in real applications. So I first want a tool to test the driver and protocol. Thus, the application for the first phase is a protocol tester that provides command line interface and several diagnostic commands / functions.

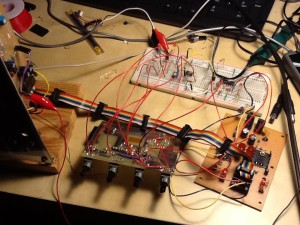

Inter Module Communication

I’m going to try making a digital communication bus for synthesizer modules.

Analog synth has a very simple control language which is voltage. Any message is translated to voltage that can be read by any modules that accept voltage input. So for example, VCO output is basically audio output but also can be used as control voltage of some other modules, such as VCO cross modulation.

This simple data exchange methodology makes analog synthesizer very versatile and flexible. However, as a drawback, patch wiring would become too complicated as you make complex module network.

One solution for making the wiring simple is to use a single common data bass where all modules are connected, and exchange data selectively using some software. Apparently, making such a bass for analog signals is impossible or extremely difficult. So I’m going to try making it using a digital bass.

Basic Study of Voltage Controlled Envelope Generator – Full Calculation Approach

I did basic study of voltage controlled envelope generator based on analog circuit approach. However, I found the implementation quite complex, although its quality was good. So, I next tried another approach that has simpler circuit. This version calculates the EG curve using micro processor, and makes analog output using PWM with minimum external filtering circuit.

This version is inspired by Tom Wiltshire‘s Voltage Controlled ADSR Envelope Generator.

Basic Study of Voltage Controlled Envelope Generator – Analog Approach

I’ve started studying voltage controlled envelope generator designs, since I have several use cases of it.

I’ve started studying voltage controlled envelope generator designs, since I have several use cases of it.

An envelope generator usually is implemented by an RC charging circuit with potentiometers as resistors. However, such design does not capable of quick parameters change. So voltage control (or digital control) functionality is necessary for better articulation. Also, non-potentiometer control is crucial to polyphonic voices.

There are several approaches to design voltage controlled envelope generators. This article describes about an analog approach which I tried first.